As a passionate researcher, I am thrilled to share my findings on the remarkable advancements made in the field of manufacturing through the introduction of lsr injection molding machines. These cutting-edge machines have revolutionized the production process and opened up new possibilities for product differentiation.

The Power of LSR Injection Molding Machine

The utilization of LSR (Liquid Silicone Rubber) injection molding machine has brought about significant improvements in manufacturing efficiency and product quality. With its precise control over temperature, pressure, and curing time, this technology allows for highly accurate and consistent production of silicone-based products.

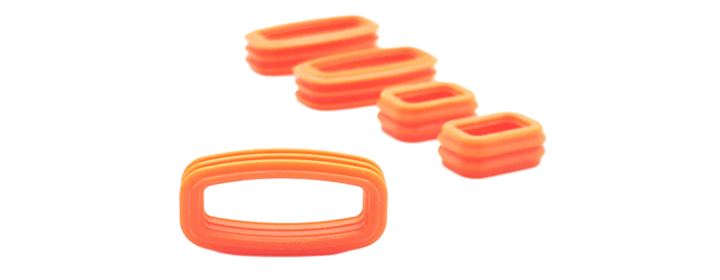

LSR injection molding machines offer exceptional versatility by enabling manufacturers to create complex shapes with intricate details that were previously unattainable. This capability has paved the way for innovative designs that captivate consumers’ attention while meeting their specific needs.

JVTECH: A Pioneer in LSR Injection Molding Technology

In my research journey, I came across JVTECH – a leading manufacturer at the forefront of LSR injection molding technology. Their state-of-the-art machines combine precision engineering with advanced software integration to deliver outstanding performance and reliability.

JVTECH’s commitment to continuous innovation is evident in their development of customized solutions tailored to meet diverse industry requirements. By collaborating closely with clients, they ensure seamless integration into existing production lines while maximizing productivity and cost-effectiveness.

Understanding Overmolding: Expanding Design Possibilities

An intriguing concept related to LSR injection molding is overmolding – a technique that involves combining multiple materials or colors within a single molded part. This method enables designers to enhance functionality, aesthetics, or both simultaneously.

Overmolding offers endless opportunities for product differentiation, allowing manufacturers to create visually striking and ergonomic designs. By incorporating soft silicone elements onto rigid substrates, products can achieve a perfect balance between comfort and durability.

Furthermore, overmolding enhances product performance by providing additional functionalities such as improved grip, shock absorption, or insulation. This technique has been widely adopted in various industries ranging from automotive to consumer electronics.

Click what is overmolding.

The Future of LSR Injection Molding

In conclusion, the introduction of LSR injection molding machines has revolutionized manufacturing processes by enabling precise production of complex silicone-based products. JVTECH’s expertise in this field further amplifies the potential for innovation and customization.

With the integration of overmolding techniques into design practices, manufacturers can differentiate their products in terms of aesthetics and functionality while meeting consumers’ evolving demands. The future holds immense possibilities for LSR injection molding technology as it continues to shape our world with its limitless potential.