Have you ever wondered how manufacturers create complex and durable products? Well, one innovative technique that has gained popularity in recent years is two shot overmolding. This process involves injecting two different materials into a single mold to create a finished product with multiple layers or components. Let’s dive deeper into this fascinating manufacturing method!

The Magic Behind Two Shot Overmolding

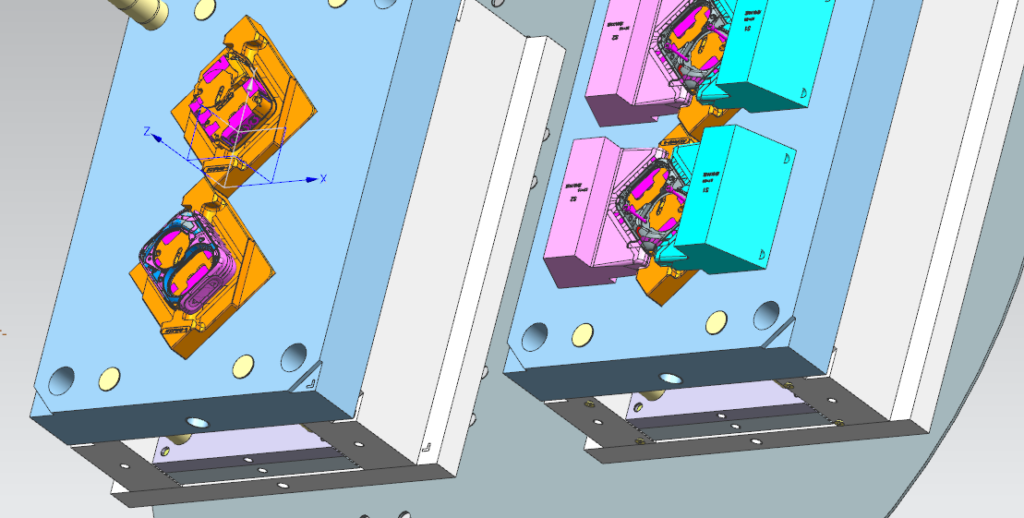

In traditional injection molding, only one material can be injected into the mold at a time. However, with two shot overmolding, manufacturers can use two different materials simultaneously. This opens up endless possibilities for creating products with enhanced functionality and aesthetics.

By combining materials such as hard plastic and soft rubber, manufacturers can achieve improved grip and comfort in handheld devices like toothbrushes or power tools. Additionally, this technique allows for the integration of multiple colors or textures within a single product without the need for additional assembly steps.

The Role of JVTECH in Advancing Two Shot Overmolding

When it comes to pushing the boundaries of two shot overmolding technology, JVTECH stands out as an industry leader. With their state-of-the-art facilities and expertise in precision engineering, they have revolutionized the way multi-material products are manufactured.

JVTECH’s team of skilled engineers works closely with clients to design molds that meet their specific requirements. They utilize advanced software simulations to optimize part designs and ensure seamless compatibility between different materials during production.

Furthermore, JVTECH’s commitment to quality control guarantees that each finished product undergoes rigorous testing before leaving their facility. Their attention to detail ensures that every aspect of the two shot overmolded parts meets or exceeds industry standards.

The Versatility of 2k Injection Molding

Another technique closely related to two shot overmolding is 2k injection molding. This method involves injecting two different materials sequentially, rather than simultaneously, into a mold. While it may not offer the same level of complexity as two shot overmolding, it still provides numerous advantages.

With 2k injection molding, manufacturers can create products with varying hardness or flexibility within a single component. This versatility makes it ideal for applications such as automotive interiors, where both comfort and durability are crucial.

In addition to enhancing product performance, 2k injection molding also reduces production costs by eliminating the need for secondary assembly processes. By consolidating multiple parts into one during the manufacturing stage, manufacturers can streamline their operations and achieve greater efficiency.

The Bottom Line

Two shot overmolding has revolutionized the manufacturing industry by enabling the creation of complex and functional products in a single step. With JVTECH’s expertise in precision engineering and dedication to quality control, this innovative technique continues to push boundaries and deliver exceptional results.

Whether through two shot overmolding or its cousin technique of 2k injection molding, manufacturers now have more options than ever before when it comes to designing high-quality products that meet diverse customer demands.